Advantages of Iron Machine Bending

1. Closed-Loop Electro-Hydraulic Servo Control Technology

2. Holland CT12 CNC Controller System

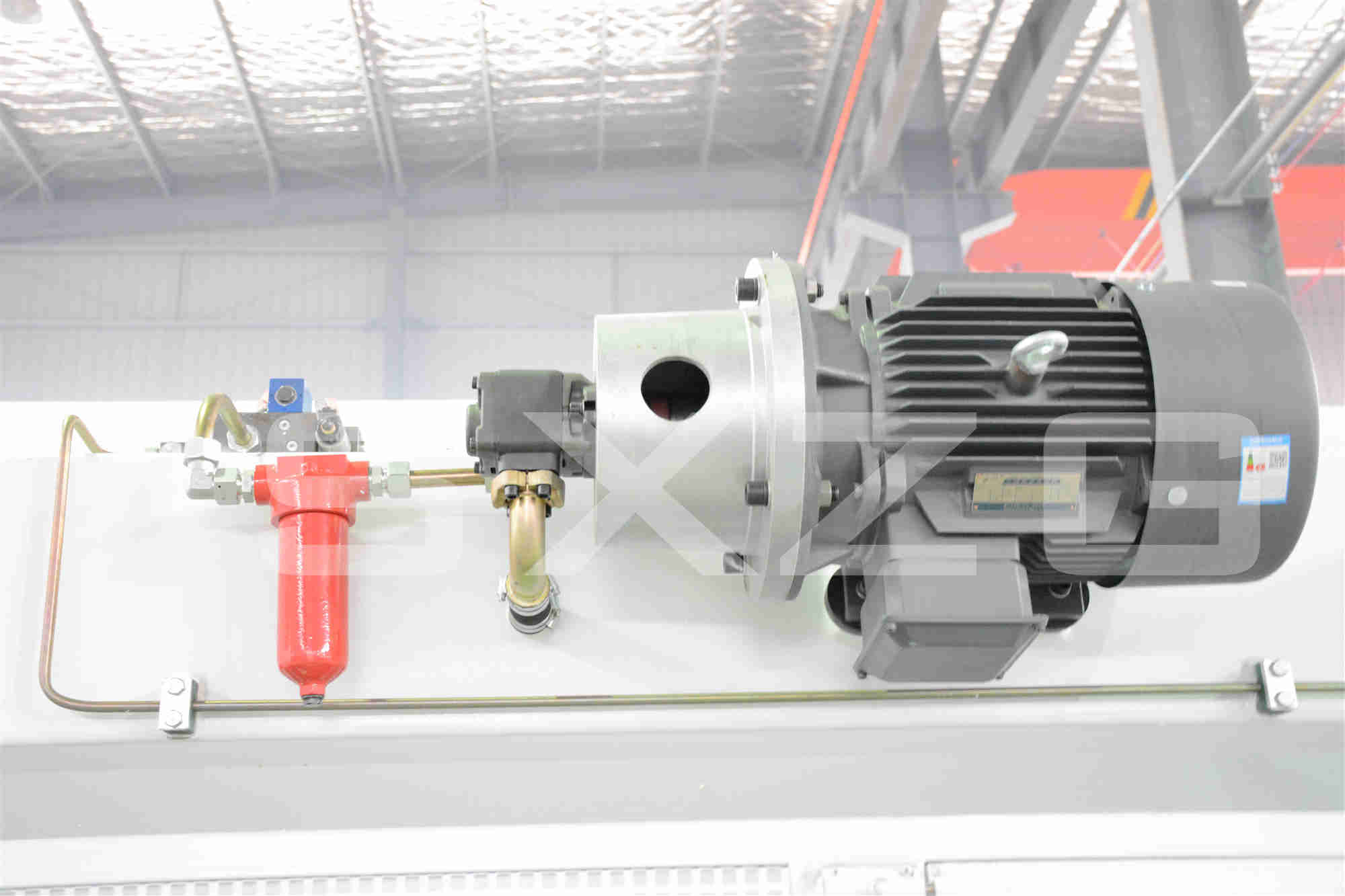

3. Germany Siemens Main Motor

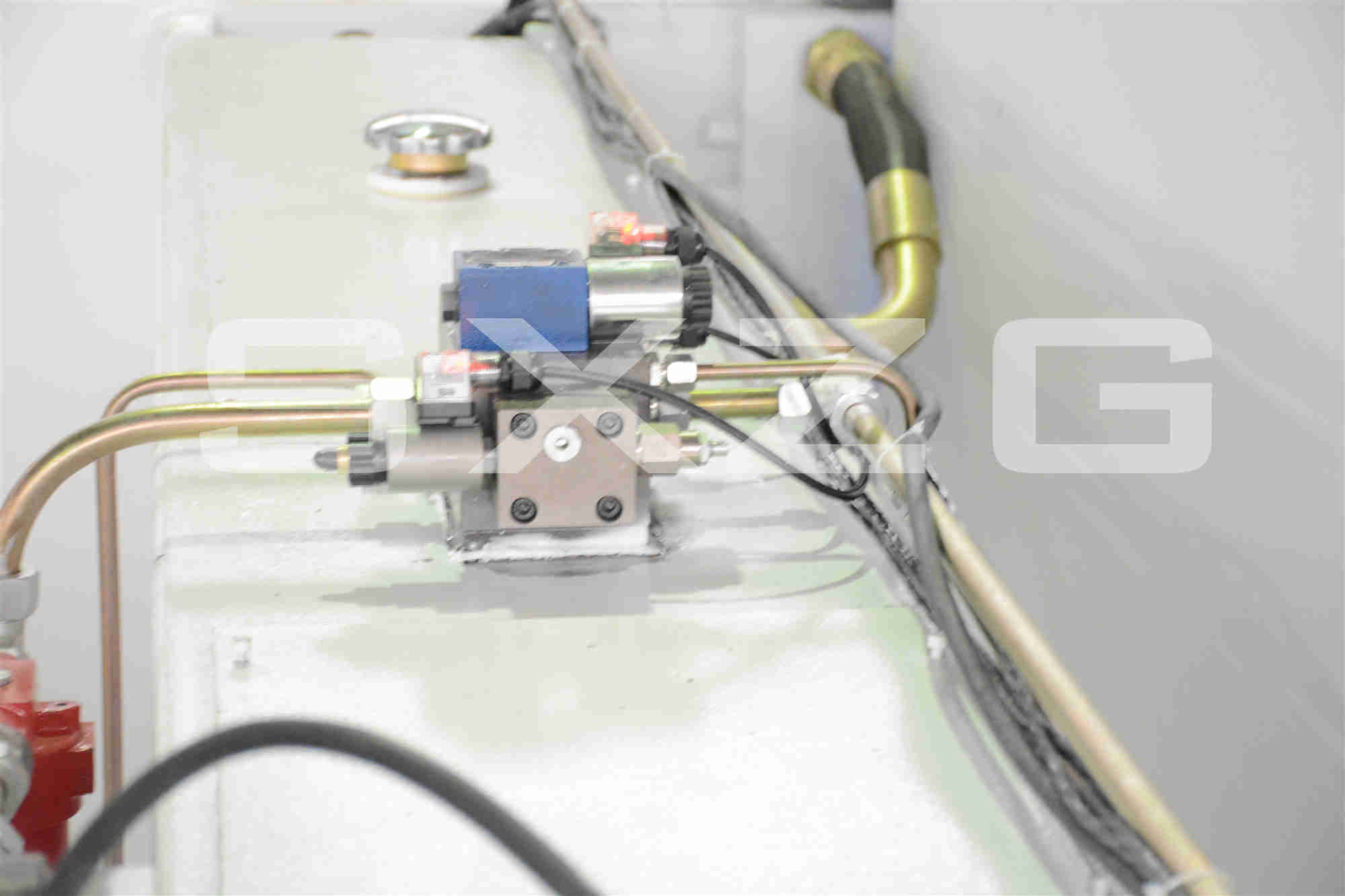

4. Bosch-Rexroth Hydraulic System

5. France Schneider Electrics

6. France Fagor Grating Ruler Control Y1 and Y2 Axis (0.01mm)

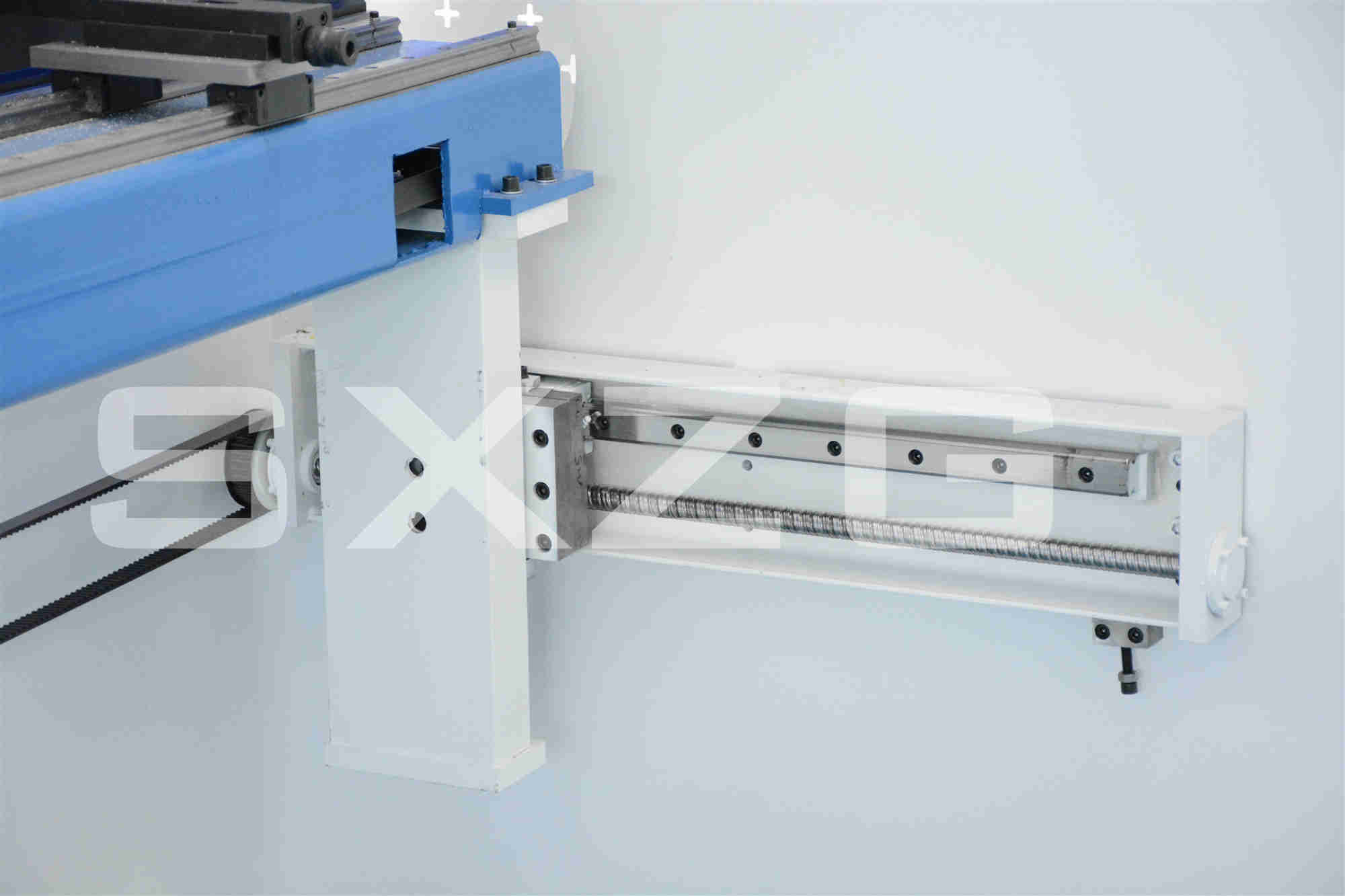

7. Taiwan HIWIN Ball Screw and Linear Guide, X Axis up to 0.01mm

8. Mechanical Crowning System Managed By CT12 Controller

9. Germany EMB Oil Tube Connectors

10. SXZG Top & Bottom Tool Clamps

CT12 Controller Features

1. With servo motor, use CAN bus control.

2. With HD colorful touch screen.

3. Support angle bending, system can calculate the bending depth automatically.

4. Support length bending, system can calculate the back gauge retraction distance automatically.

5. Support bending angle correction.

6. Support bending length correction.

7. Slider position control, back gauge position control.

8. Support Retraction function, which can prevent the interference between material and back gauge device.

9. X\Y axis guide mode (With password protection).

10. Support manual movement function (Password protection).

11. Menu programming style.

12. Up to 220 programs can be saved, and each program can support up to 24 steps.

13. Support up to 60 punches.

14. Support up to 60 dies.

15. Support Software limit function.

16. Support off memory.

|

CNC Sheet Bending Machine

SXZG Series metal cutting and bending machine features the crowning system for improved quality, a servo driven back gauge system for increased speeds. Also has increased working speeds, stroke, daylight, and pressing capacities of machines. The future - as a result of rising energy costs and increasingly cost efficient speed-controlled drives offered on the market, variable-speed solutions are on the advance.

Mini bending machine is fully in accordance with European standards, high precision, high security. |

|

|

EUROPEAN DESIGN STYLE

EURO series one step beyond robustness, Engergy-efficient, reliability,precision and performance make Euro an election model. |

Back of machine |

|

|

Germany Siemens Motor

Using Siemens motors guarantee the machine service life and improve the machine working stability |

Bosch Rexroth hydraulic Valve

Germany Bosch Rexroth integrated hydraulic transmission with high reliability, integrated hydraulic system can effectively alleviate problems caused by leakage of hydraulic fluid |

|

|

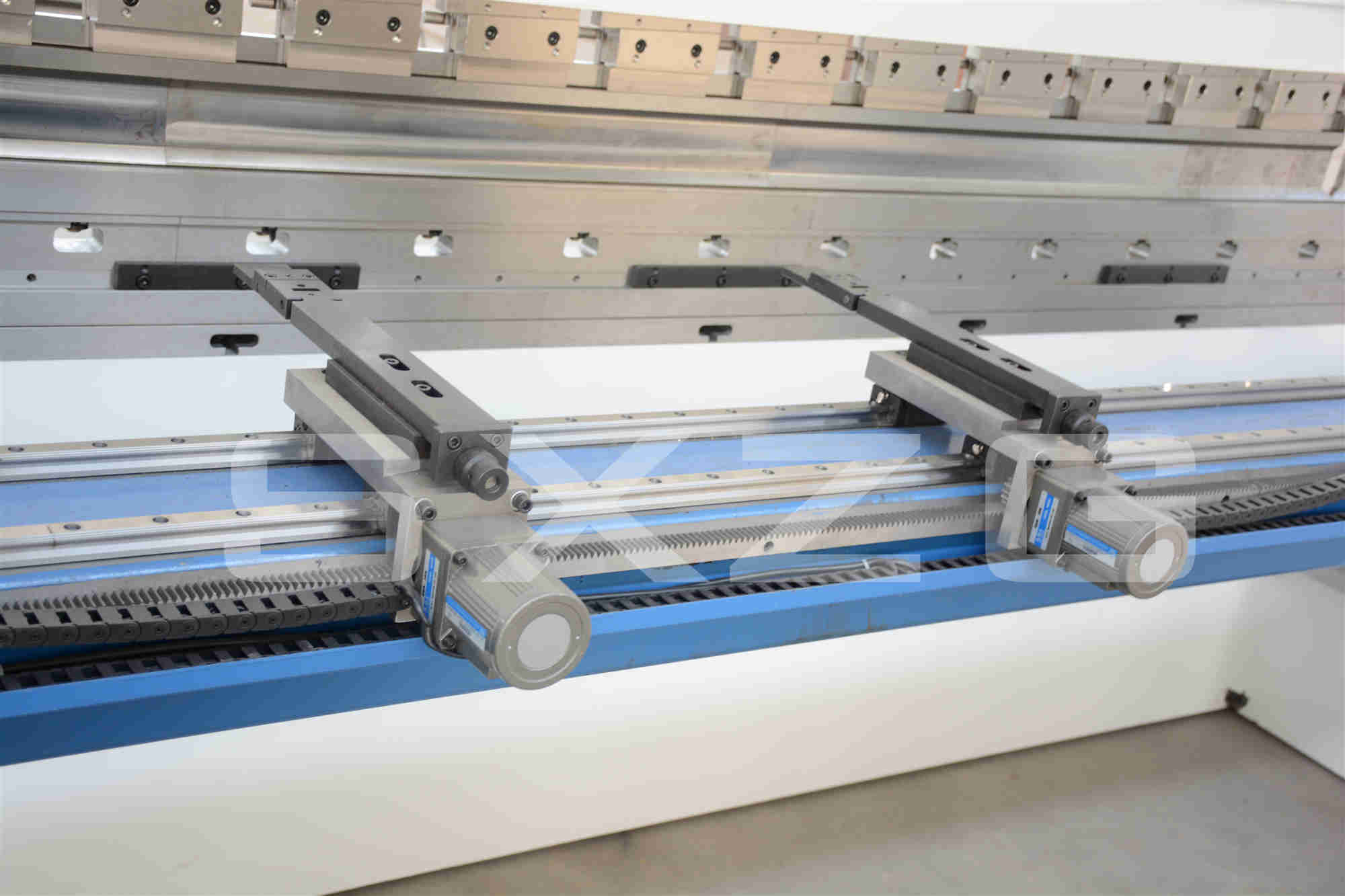

Hiwin Ball Screw And Linear Guide Rall

Using Taiwan HIWIN Ball Screw and linear guider to improve the machine backgauge accurancy |

Germany EMB tube

Using Germany EMB tube and connectors reduce the odds against welding slag jam into the valves and affect oil flowing |

|

|

Front Plate Support

Movable front material support on HIWIN linear guider, can move left and right by hand very easy.

Quick Clamp

It's very convenient to change the tools. |

Mechanical Crowning

Optional electric mechanical crowning, improving the precision of bending angle and linearity, can be controlled by DA52S controller(C-Axis) |

|

Optional Components

|

|

|

Backgauge up and down

Optional Servo motor drive R Axis-Backgauge up and down |

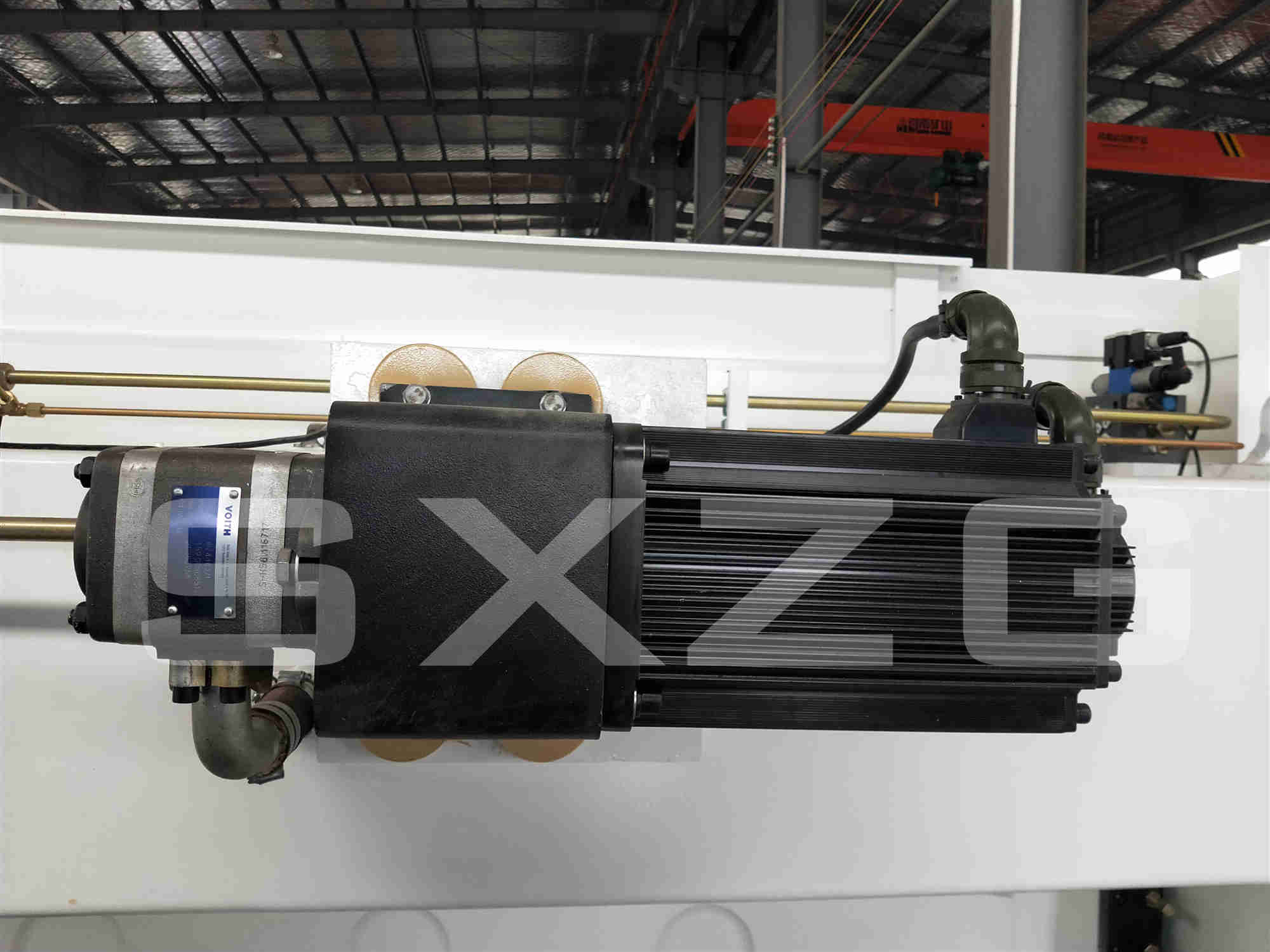

Main Motor Sevo Motor

Save electricity costs; Low noise; Low oil temperature, extend the life of the seal |

|

|

Italy DSP Laser protection

Optional Italy DSP laser protection, protecting the workers' fingers |

Motorized Stopper Fingers Z1 and Z2 |

|

|

Hydraulic Crowning

Optional hydraulic crowning, improving the precision of bending angle and linearity, can be controlled by CT12 controller

(C-AXIS) |

Optional Segment Die

Press brake segmented die are available for your choice |

|